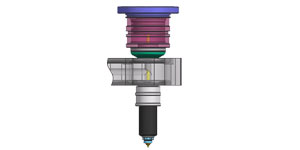

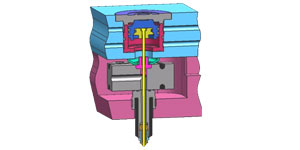

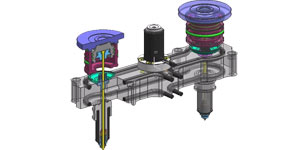

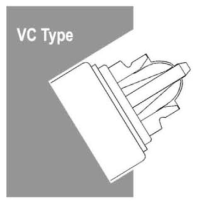

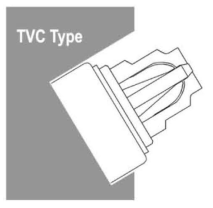

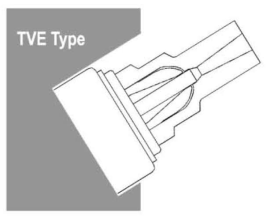

Valve Gate Systems

Valve gate nozzle is used for direct injection molding where cosmetic appearanceis critical (No gate vestige).

The nozzles are design for processing General and Engineering material,With or without additives giving a wide range of application for highly accurate shut off design.

Salient Features

- Clean surface finish (no gate vestige).

- Large gate diameter (reduce fill time).

- Minimum injection pressure loss.

- Low shear rate.

- Long life with minimum wear and low maintenance.

- Defined gate opening for optimal process control (Sequence timer).

- Optimize Processing windows.

- Short cycle time.

- Optimal temperature Control.

- Minimizes in-molded stress and warp